Precision slitting Dept.

Business introduction

An enterprise providing slitting processing of precision stainless steel materials and various non-ferrous metal materials.

Processing of metal materials used in electronic parts, automotive parts, smartphone parts, OA equipment, etc.

A first-level agent of Japanese factory products recommending high-performance materials from Japan.

As a branch center in South China, it is committed to traceability and thorough quality control, and is equipped with levelers and heavy plate cutting machines.

The biggest advantage of the enterprise is that it can perform ultra-precision slitting processing of light, thin and ultra-fine materials and it is highly thought of in various fields.

As electronic equipment is getting smaller, lighter and more environmentally friendly, the enterprise provides technical support for energy-saving materials.

The enterprise can provide the most suitable materials and processing technology unique to it according to clients' purposes to contribute to clients’ high-quality and high-precision products.

Leading edge

Leading slitting technology and capability in China

Leading slitting technology and capability in China

The slitting processing of metal materials and specifications are carried out in dust-free workshops.

| Material | Various stainless steel materials, non-ferrous metal materials (nickel, pure copper, phosphor bronze, aluminum, titanium, non-crystalline materials, precious metals, PP films), silicon steel sheets, metal composite materials, electroplating materials, non-magnetic materials, materials with high flatness, micro-crystalline materials, mirror materials, low-nickel 304 substitute materials, dual-phase steel with high strength, metal foil materials, black electrolytic coloring materials, high-strength aluminum materials, etc. |

|---|---|

| Specifications | Ultra-precision slitting: thickness: 0.01 to 1.5 mm, width: 0.8 to 320 mm Precision slitting: thickness: 0.05 to 3.0 mm, width: 5.0 to 1,219 mm |

| Industry | Automobile, mobile devices, LCDs, OELDs, medical treatment, batteries, capacitors, semiconductors, superconductors, solar power generation, OA equipment, game consoles, etc. |

| Purpose | Related parts of EV, HV and FCV, keys, window moldings, antennas, door hinges, circuit boards, various current sensors, capacitors, connectors, motors, integrated cables, transformer cores, sensor cores, inner tabs, electrode foils, isolators, SIM cards, tab frames, flexible substrates, micro-switches, snap domes, metal stencils, OA equipment and other electronic components. |

What we can process with high precision in dust-free workshops is ultra precision slitting with the minimum width of 0.8 mm.

Compared with ordinary precision slitting, burr-free processing can reduce burrs and bends and improve flatness, contributing to high-performance parts.

Leading service strength in China

We can handle small-batch shipment in a short delivery time.

We can make in advance base metal inventory of various materials according to the forecast provided by clients and carry out slitting processing and delivery after receiving orders.

To reduce clients’ inventory pressure and financial burden, we have established and improved the timely supply system, “materials and quantity required by clients”.

Leading proposal capability in China

We recommend high-performance materials to clients to overcome “difficulties”.

We recommend high-performance materials to clients based on their requirements of magnetism, flatness and high hardness.

We sell a variety of stainless steel materials, non-ferrous materials (nickel, pure copper, phosphor bronze, aluminum), composite materials, electroplating materials, dual-phase steel materials, foil materials and other materials.

Leading service center in China

We process materials supplied by clients.

We process materials supplied by clients. That is, we process materials provided by clients according to their requirements, so as to reduce their inventory risk and financial burden.

Bonded transfer of foreign currencies and deliveries in Hong Kong are supported for general trade.

Cooperation can be carried out according to the currencies and transaction modes that clients want.

Settlements in RMB, USD, HKD and JPY are supported.

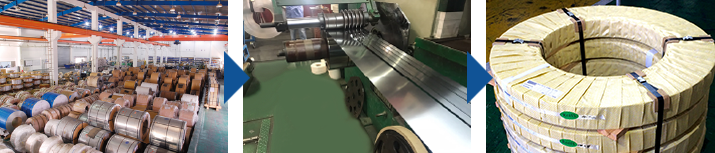

Equipment introduction

| 7 precision slitting lines | Line 1 (width: 1,250 mm), Line 2 (width: 650 mm), Line 3 (width: 390 mm), Line 4 (width: 650 mm), Line 5 (width: 300 mm), Line 6 (width: 300 mm) , Line 7 (width: 300 mm) |

|---|---|

| 1 ultra-precision slitting line | Line A (width: 320 mm) |

| 3 cutting machines | Machine 1 (thickness: 2.5 to 13.0 mm), Machine 2 (thickness: 0.3 to 3.0 mm), Machine 3 (thickness: 0.3 to 3.0 mm) |

| 1 precision leveler | Leveler A (thickness: 0.1 to 1.5mm, width: 650 mm, length: 2,000 mm) |

-

Precision Slitter Line 1

-

Cutting Machine 1

-

Precision leveler and cutting machine

Inspection equipment

The most cutting-edge inspection equipment of Quality Assurance Department ensures high quality of products.

-

Hardometer

-

Digital micrometer

-

Microscope

-

Thickness digital photometer

-

Altimeter

-

Straightness measuring instrument

Contact information of Precision Slitting Department

Tel (+86)0760-2361-8640

Fax (+86)0760-2361-8648