Wire processing & coating Dept.

Business introduction

The Company provides integrated processing from iron wire processing to surface dipping.

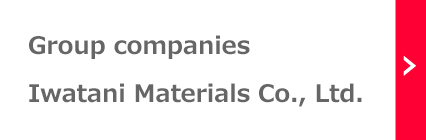

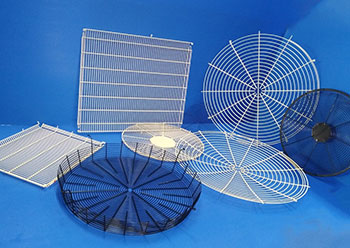

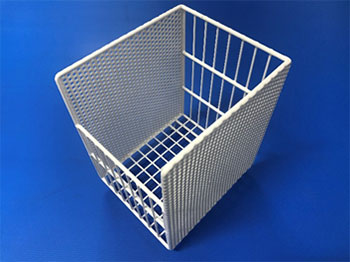

It engages in manufacturing and sales of fan guards of outdoor units of air conditioners, dishwasher baskets, freezer shelves and other wire coating products. Taking the advantages of mature wire processing technology and quality management system in Japan, it can meet the requirements of air conditioning manufacturers and dishwasher manufacturers in Japan and China.

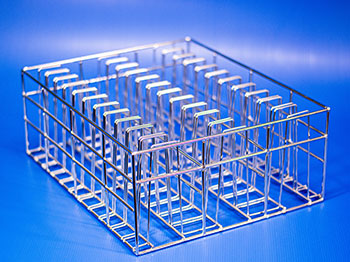

It also manufactures turnover baskets, cleaning baskets and other appliances used in factories and provides clients with proposals, making factories more efficient.

Its professional process design and die design and manufacturing teams with years of industry accumulation and technical experience can provides customers with practical solutions.

-

Fan guards of outdoor units of air conditioners

-

Dishwasher baskets

-

Freezer shelves

-

Parts cleaning baskets

Leading edge

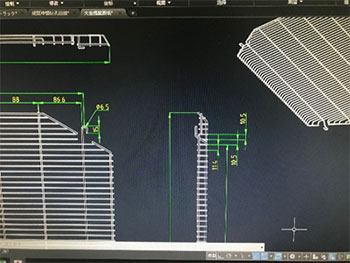

Technical capability of wire processing

It can process metal wires of complex shapes.

| Material | Iron and stainless steel wires |

|---|---|

| Wire diameter | φ1.0~φ10.0mm |

With years of experience and practical results, the Company works with 3D manufacturers through die manufacturing to deal with complex product structures.

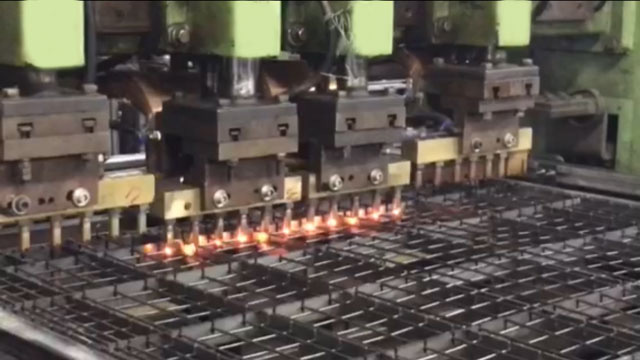

Automatic welding process

Automatic welding process ensures stable quality.

Automatic welding process ensures stable quality and raises productivity.

Processing capability of surface dipping

High-quality surface coating through large-scale automatic flow dipping equipment

| Wire diameter of surface dipping | PE dipping, PP dipping and nylon dipping |

|---|---|

| Specifications | Maximum size: 1,300 mm x 1,300 mm |

The Company provides the best surface treatment based on technology and quality management in Japan. It also provides commission processing.

※ Stainless steel electrolysis, powder spraying, fluorine coating, electrophoresis, electroplating, etc

Proposal strength of design team

It can meet clients’ requirements with our previous experience and CAD design proposal strength.

The design team and technical team can satisfy clients with whatever they want and deal with complex structures and special surface coating.

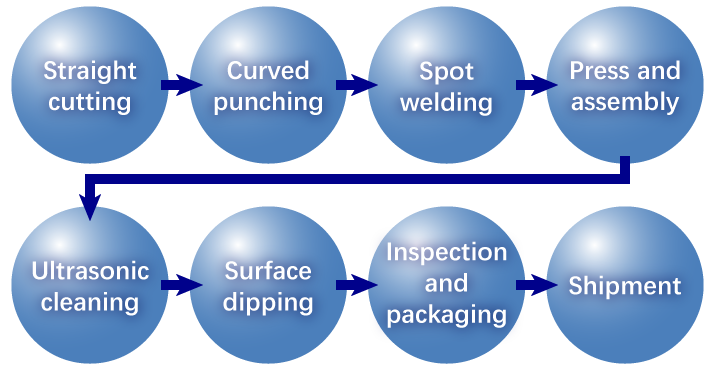

Process

All projects are done in the Company, including raw materials and products.

Equipment introduction

| High-speed straight cutter | 11units |

|---|---|

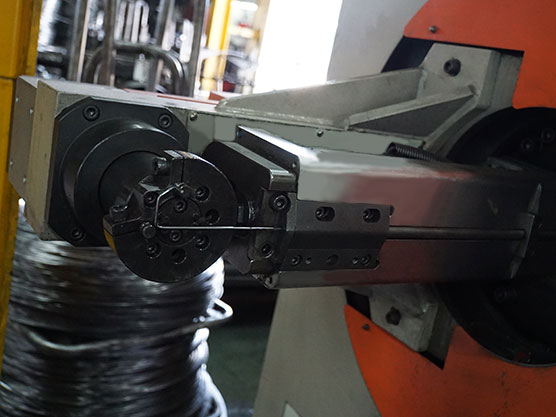

| Automatic 3D bender | 3units |

| Press (5 tons to 200 tons) | 25units |

| Spot welding (15 KVA to 250 KVA) | 60units |

| Automatic welding machine | 11units |

| Ultrasonic cleaning equipment | 1unit |

| Large-scale automatic flow dipping equipment | 2units |

| Image automatic inspection machine | 1unit |

| Salt spray tester | 1unit |

-

Automatic spot welding machine (multiple welding spots)

-

Automatic spot welding machine (large width)

-

3D bender

-

Ultrasonic cleaning production line before coating

-

Large-scale flow dipping production line

-

Image automatic inspection machine

Contact information of Wire Processing Department

Tel (+86)0760-2361-8559

Fax (+86)0760-2361-8651