The company will meet customer demand by utilizing past experience and actual results consistently.

| Material | Various copper materials:C19720、C1100、C5210、C5191 etc. Various aluminum materials:A5052、A1050 etc. Various stainless steel:SUS304、301、430、631 |

|---|---|

| Size | Board Thickness 0.1mm to 3.0mm, board width max 300mm |

| Processing Item | Precision stamping, assembly, riveting, automatic tapping, insert molding |

| Component cleaning | Hydrocarbon (JX/NX Cleaning) |

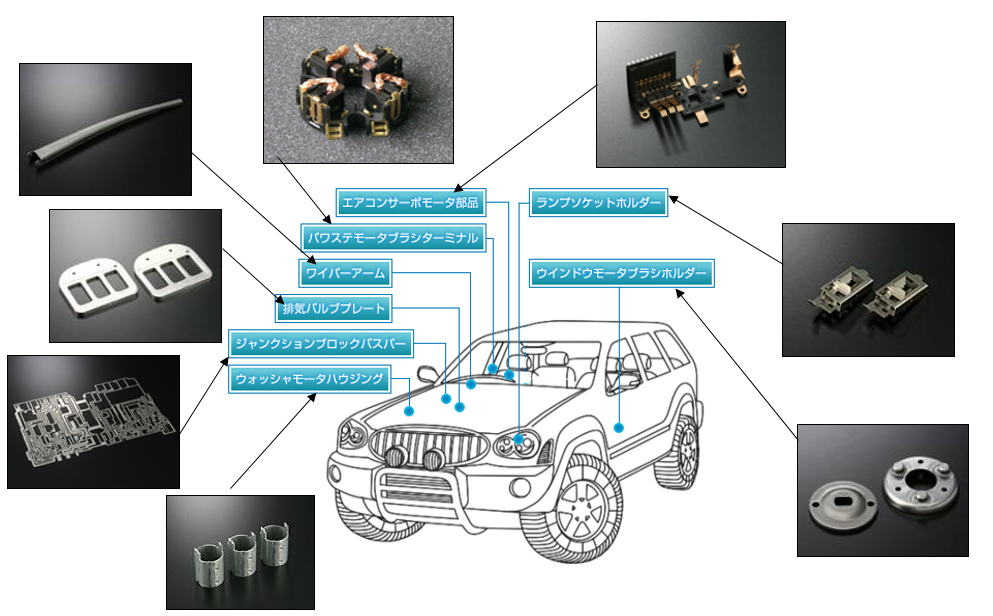

| Main Purpose | Automotive-related, OA-related, mobile-related, connector-related |

| Major Customers | (Slightly omitted, ranked in no particular order) Sumitomo Denso, Yazaki , Fujikura, Asmo, Ricoh, Kyocera, Konica Minolta, Fuji Xerox, Citizen, Sharp, Panasonic, Ushio,Nittan, etc. |

Achieving precise processing by relying on Japan's advanced technology

Reassuring tracking and quality management

Extensive material purchase and sales system

■Our company is located in the factory area of Zhongshan Iwatani Co., Ltd., which is the premier stainless steel and non-ferrous rolling material center in the industry. We are able to consistently complete the entire process from material purchase, notch processing to stamping processing. We enjoy advantages in cost competitiveness and wide choices of materials.

■It can realize bonded transfer and RMB general trade. Payment can be made in any currency such as U.S. dollars, Hong Kong dollars, renminbi, yen, etc.

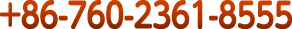

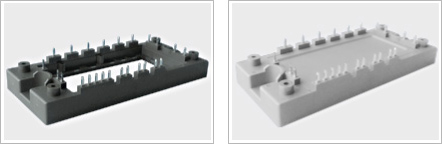

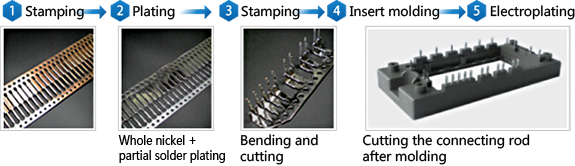

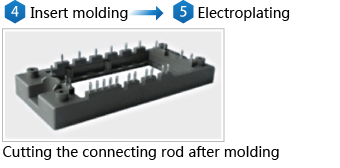

Power semiconductor devices

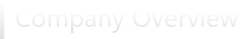

Processing Examples

Copper and Copper Alloy

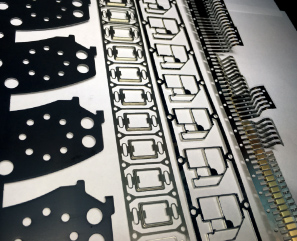

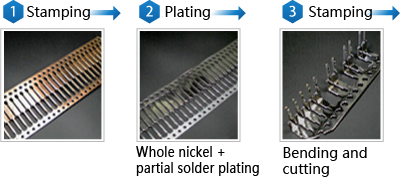

Smartphone backplane

Processing Examples

GM55 (high-intensity aluminum) or US (spring)

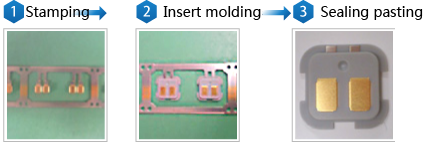

Charging terminal

In order to reduce costs, a gold-plated bar-shaped material is used. In the resin molding processng, the insert molding is performed in a FOUP shape in order to improve the efficiency.

Processing Examples

SUS (spring) gold plated material